Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

In recent years, the flooring industry has witnessed a remarkable transformation with the advent of rigid-core luxury vinyl flooring. This innovative product combines the aesthetic appeal of traditional materials like hardwood and stone with the durability and practicality of vinyl. Central to this revolution are the rigid-core luxury vinyl flooring factories, which are at the forefront of producing these exceptional flooring solutions. In this blog, we'll explore the fascinating world of these factories, delving into their production processes, technological advancements, and the reasons behind the soaring popularity of rigid-core luxury vinyl flooring.

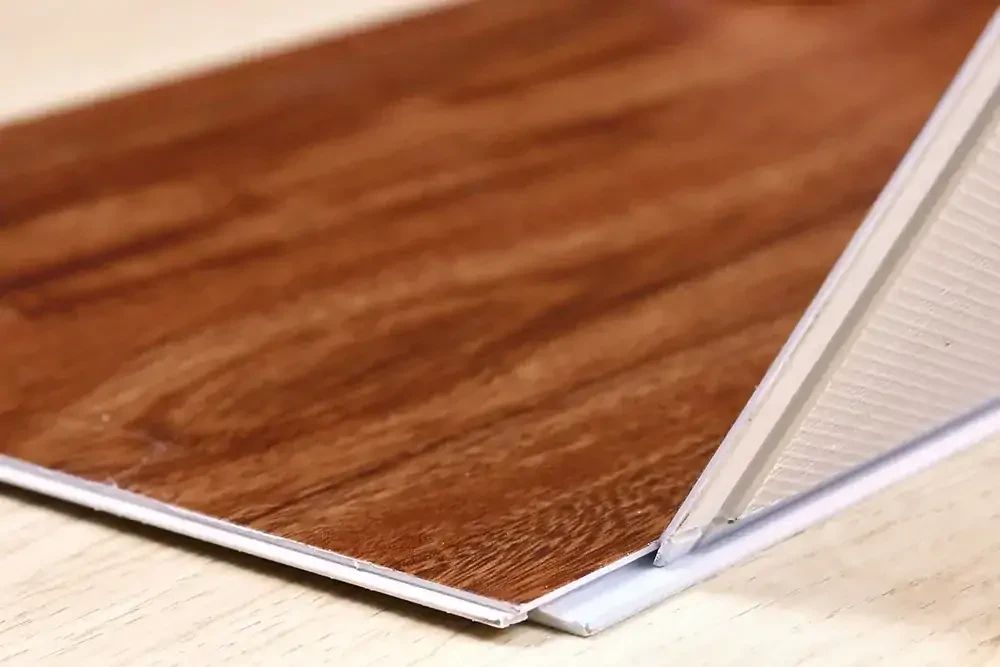

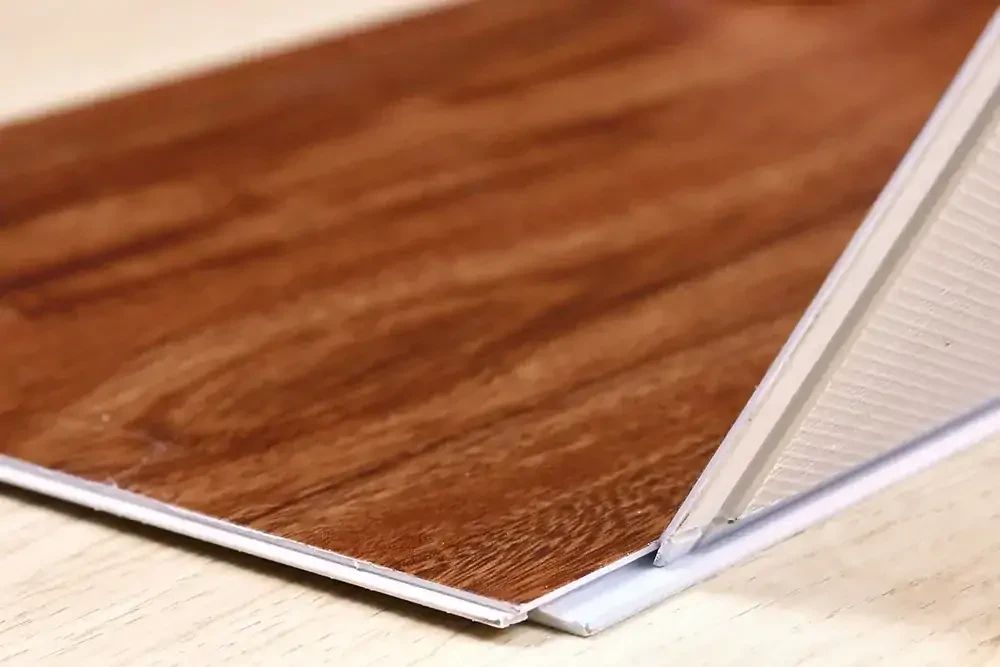

Before diving into the intricacies of rigid-core luxury vinyl flooring factories, it's important to understand what sets this flooring apart. Rigid-core luxury vinyl flooring, often referred to as rigid-core LVT (luxury vinyl tile) or SPC (stone plastic composite), is known for its enhanced stability and robustness. Unlike traditional vinyl flooring, which can be prone to warping and bending, rigid-core luxury vinyl features a dense, solid core that provides exceptional dimensional stability.

This flooring is designed to mimic the look and feel of natural materials while offering superior performance characteristics. It is waterproof, resistant to scratches and stains, and incredibly easy to maintain. These qualities make it a popular choice for both residential and commercial applications.

The production of rigid-core luxury vinyl flooring is a complex and highly sophisticated process that takes place in state-of-the-art factories around the world. Let's take a closer look at the key stages involved in the manufacturing of this cutting-edge flooring.

1. Material Sourcing and Preparation

The journey of rigid-core luxury vinyl flooring begins with the sourcing of high-quality raw materials. These factories use a combination of limestone, PVC (polyvinyl chloride), and stabilizers to create the rigid core layer. The selection of these materials is crucial, as it directly impacts the durability and performance of the final product.

Once the raw materials have been procured, they undergo a meticulous preparation process. This involves grinding limestone into a fine powder and blending it with PVC and other additives. The mixture is then heated to form a homogenous compound that will serve as the core layer.

2. Extrusion and Calendering

The prepared mixture is fed into an extrusion machine, where it is melted and formed into a continuous sheet. This sheet is then passed through a series of rollers in a process known as calendering. Calendering ensures that the sheet achieves the desired thickness and uniformity. The resulting core layer is exceptionally strong and stable, forming the backbone of the rigid-core luxury vinyl flooring.

3. Adding the Decorative Layer

One of the most appealing aspects of rigid-core luxury vinyl flooring is its ability to replicate the look of natural materials. This is achieved through the application of a high-resolution decorative layer. Using advanced printing technology, factories can produce intricate designs that mimic the appearance of wood, stone, and other materials with remarkable realism.

The decorative layer is printed onto a thin film, which is then carefully laminated onto the rigid core layer. This process not only enhances the visual appeal of the flooring but also adds an extra layer of protection.

4. UV Coating and Embossing

To further enhance the durability and aesthetics of the flooring, factories apply a UV coating. This coating protects the surface from scratches, stains, and fading caused by exposure to sunlight. Additionally, it gives the flooring a desirable finish, whether it be matte, semi-gloss, or high-gloss.

Embossing is another critical step in the manufacturing process. This technique involves pressing patterns into the surface of the flooring to create texture. For instance, wood-look vinyl may feature embossed grain patterns that mimic the feel of real wood. This tactile dimension adds to the authenticity and appeal of the flooring.

5. Cutting and Quality Control

Once the various layers are assembled and treated, the flooring is cut into planks or tiles of the desired size. Precision cutting ensures that each piece fits together seamlessly during installation.

Quality control is paramount in rigid-core luxury vinyl flooring factories. Rigorous testing is conducted at every stage of production to ensure that the flooring meets strict standards for performance, safety, and appearance. This includes tests for water resistance, impact resistance, and dimensional stability.

The success of rigid-core luxury vinyl flooring can be attributed to continuous technological advancements within the factories. These innovations have revolutionized the production process, resulting in higher-quality products and increased efficiency.

Automation and Robotics

Many rigid-core luxury vinyl flooring factories have embraced automation and robotics to streamline production. Automated systems handle tasks such as material handling, mixing, and calendering with precision and speed. This not only reduces the margin for error but also enhances production capacity.

Sustainable Practices

Sustainability is a growing concern in the flooring industry, and rigid-core luxury vinyl flooring factories are no exception. Many factories have implemented eco-friendly practices, such as using recycled materials and minimizing waste. Additionally, advancements in production technology have led to more energy-efficient processes, reducing the environmental impact of manufacturing.

Advanced Printing Techniques

The development of advanced printing techniques has been a game-changer for rigid-core luxury vinyl flooring. High-definition digital printing allows for incredibly detailed and realistic designs. Factories can now produce flooring that closely resembles rare and expensive natural materials, providing consumers with affordable yet luxurious options.

Rigid-core luxury vinyl flooring has become a favorite among homeowners, designers, and contractors for several compelling reasons.

Durability and Longevity

Thanks to its rigid core construction, this flooring is highly resistant to wear and tear. It can withstand heavy foot traffic, making it ideal for commercial spaces and busy households. Its waterproof nature also makes it suitable for areas prone to moisture, such as kitchens and bathrooms.

Easy Installation

Rigid-core luxury vinyl flooring is known for its ease of installation. Many products feature a click-lock system that allows for floating installations, eliminating the need for adhesives. This DIY-friendly approach saves time and money, making it accessible to a wide range of consumers.

Aesthetic Versatility

With a vast array of designs, colors, and textures to choose from, rigid-core luxury vinyl flooring can complement any interior style. Whether you prefer the timeless elegance of hardwood or the sleek look of stone, there's a rigid-core vinyl option to suit your taste.

The rise of rigid-core luxury vinyl flooring factories marks a significant milestone in the evolution of modern flooring. These factories combine cutting-edge technology, sustainable practices, and meticulous craftsmanship to produce flooring that excels in both form and function. As a result, rigid-core luxury vinyl flooring continues to gain popularity, offering consumers a durable, stylish, and practical solution for their flooring needs. Whether you're renovating a home or designing a commercial space, the innovative products from these factories are sure to impress.